Forging can be carried out by many methods, some of which are listed below:

Forging Processes

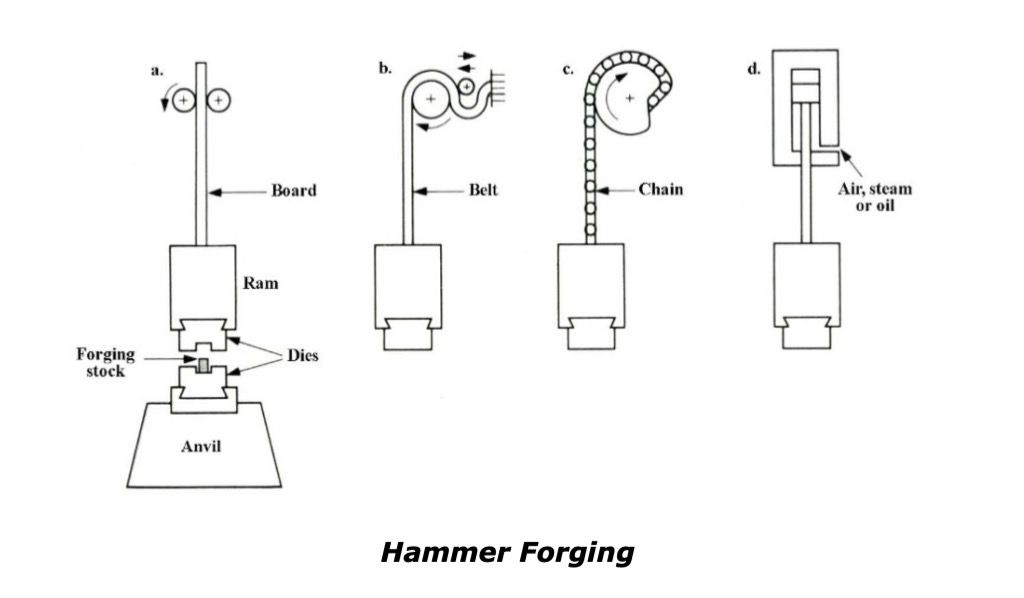

Hammer forging

For components to be used in industry, hand forging is rarely used; however, automatic hammer processes may be encountered.

Hammer forging uses the energy derived from the mass and velocity of the hammer contacting the stationary work piece.

There are two main types of hammer forging used in industry:

- Gravity drop hammers (drop forging) – this is where a forging ram is raised against gravity by chain, belt, air and steam etc., and is then allowed to fall freely to contact the workpiece.

- Power drop hammers – these are similar to the above but the power (down stroke) is a pressurised ram that intensifies the impact. The ram is air, steam or hydraulically operated, this allows for more control and hence more versatility.

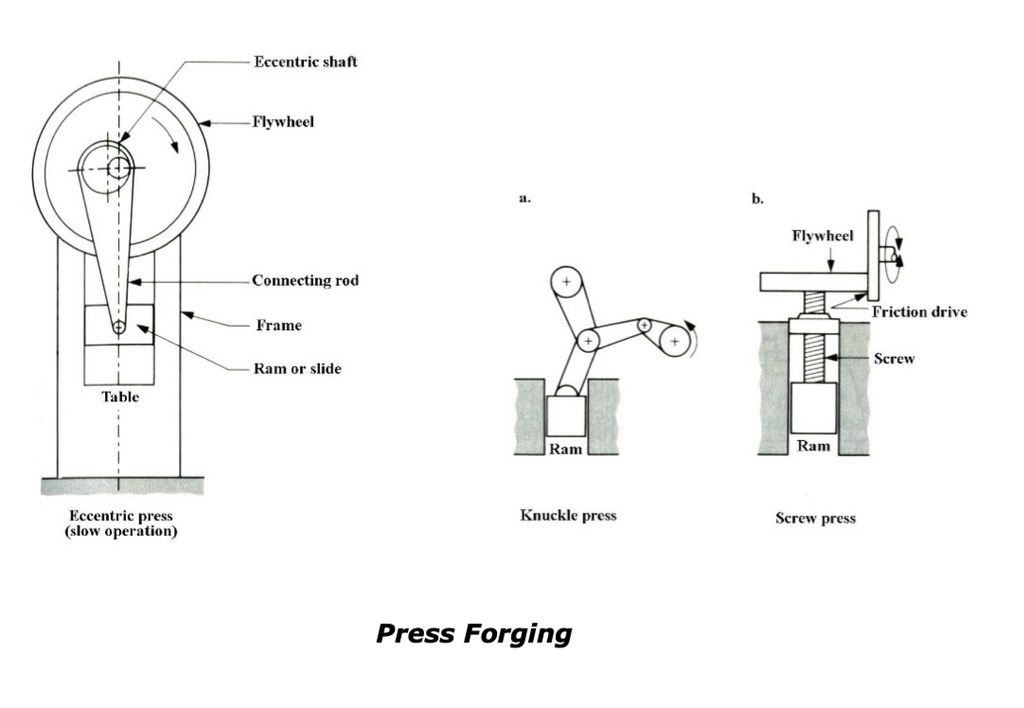

Press forging

Press forging is when force is imparted by a pressing action, generally applied to non-ferrous materials and allows a deeper flow of the metal; the specific methods used are:

-

Mechanical presses – these have a crank or eccentric type of actuation. They are limited by the inherent length of stroke but high forces can be generated. Special component dies are fitted to meet component manufacturing requirements.

-

Screw press – this uses the stored energy of a flywheel or centrifugal mass; the mass of flywheel or centrifugal mass is a limitation in itself. This system uses die inserts and is only suitable for light work.

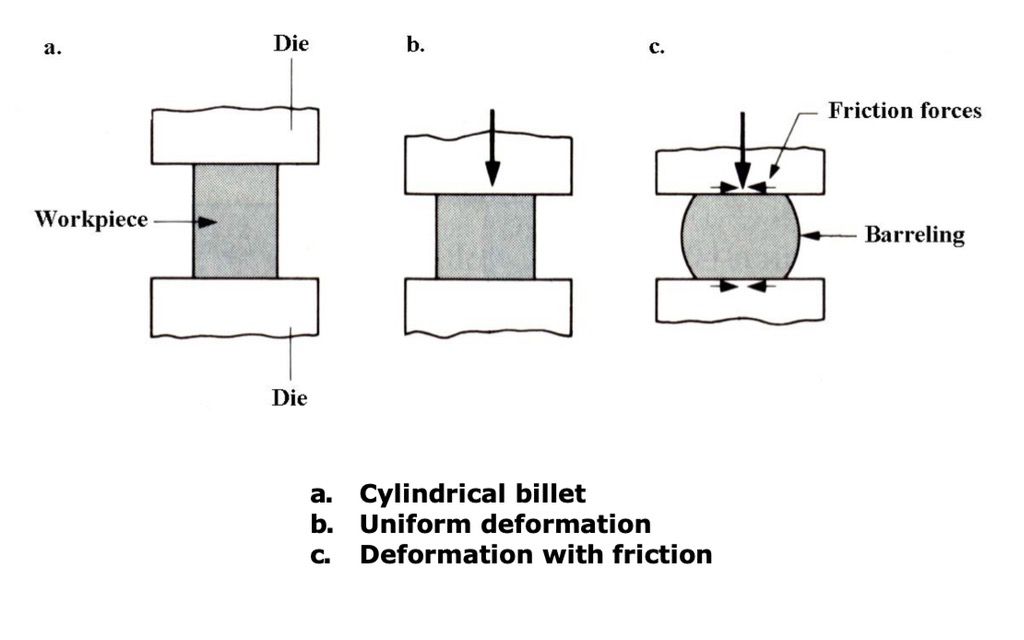

Open die forging

Two flat dies are placed in the two forging faces and a suitable heated section of material is placed on the lower die. The faces are brought together and the material is shaped by compression, sometimes termed upsetting*.

*Upsetting is often defined as either, where the cross section is increased at the expense of the length or as an intermediate forging process. This is often used with ferrous materials since there is a reduction in time with the contact of hot material & the dies hence reduces wear rates on the dies.

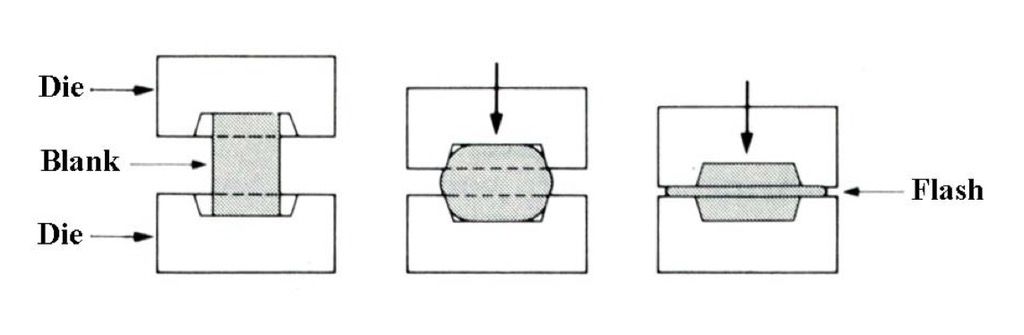

Closed die forging

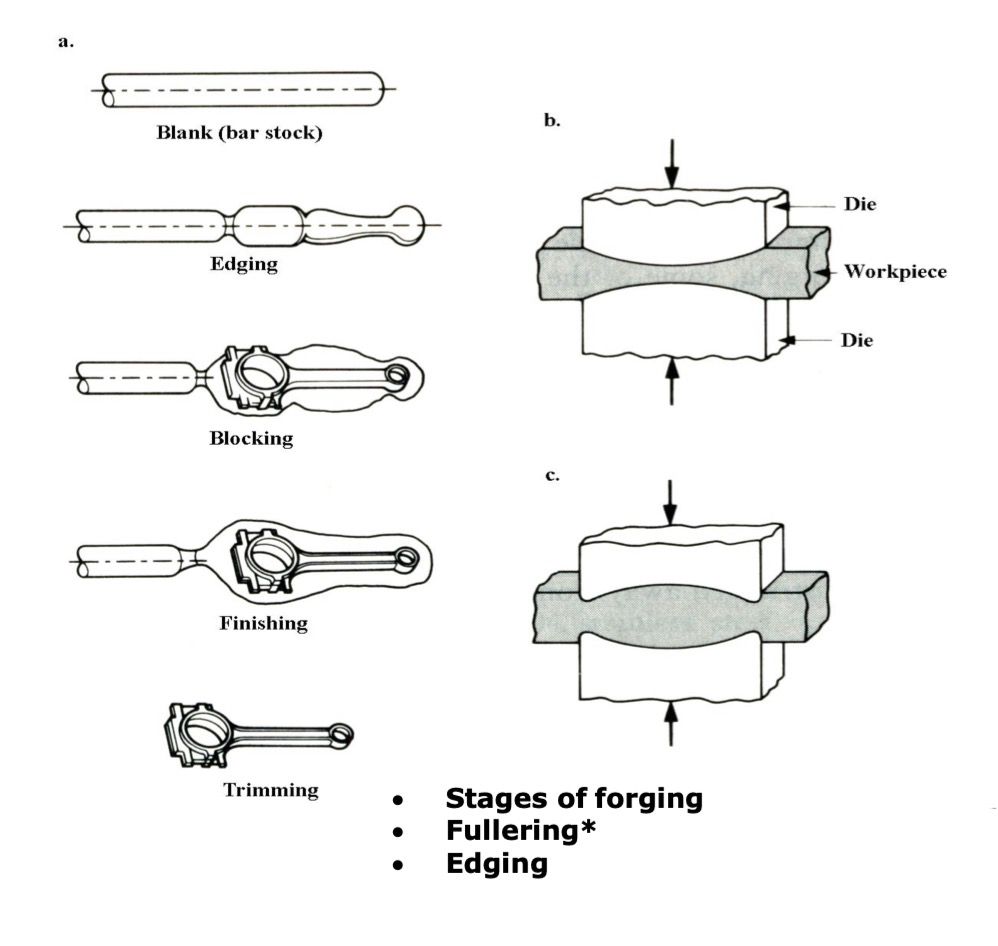

Used when special shapes are required. A sequence of forging sets have to be used: the material is shaped, part formed, formed again, possibly pierced and finally trimmed to produce components almost to size. Closed die forging produces excess metal called flash which has to be trimmed off.

Note Castings may also produce excess material along the parting line which appears similar to flash, however for castings the excess material is known as ‘finning’

To ensure the die is fully filled by the base material in all areas, the blank (base material being formed) contains more material than the finished forging. This excess material is squeezed into an area around the die called the gutter, and this excess material is now referred to as flash and is removed afterwards via fettling.

Note The area of the die where the excess material is to be squeezed into forming the flash is termed the ‘gutter’.

The die is highly polished to reduce sticking and friction as the material is deformed filling the cavity.

*Fullering is to reduce the cross sectional area and increase the length

Cold forging

Most cold working is carried out below the recrystallization temperature. Generally this is accomplished at room temperature. However, some heating of the material will increase ductility, aiding deformation of the material in the plastic range.

Operations for cold working include bending, shearing, drawing and squeezing. Cold working has some advantages over hot working. Because little heat is applied there is greater control over dimensions and the surface finish is much improved. Repeatability and increased strength are also advantages along with good directional properties.

Because no, or little heat is applied residual stresses which build up during the cold working process may require heat treatment to reduce these stresses. Additionally, in order to deform during cold working, higher acting forces are required which necessitates heavier and more powerful equipment.

Metal surfaces must be clean and free from any scale otherwise a good surface finish is not possible. Careful consideration must also be given to the directional properties required as the cold working process may not always produce the desired properties.

Cold working in the vast majority of cases has a hot working counterpart, the main difference is the equipment for cold working is more powerful in order to deform and shape the material.